19/026

Fetdeterra

Rammed Earth Specialists

Lleida

«We must give a technical response to current needs.»

«We must give a technical response to current needs.»

«We must give a technical response to current needs.»

«We must give a technical response to current needs.»

Please, introduce yourself and your Studio…

Maite Sainz de la Maza, architect and Macari de Torres, geologist engineer, founders of Fetdeterra, Innovative Earth Projects and Products.

We are technical specialists in rammed earth architecture and accredited consultants in eco-innovation, product design and technological development.

We work with users, technicians and manufacturers from the very first stages of the project to find the solution that best suits their needs.

We want to promote the use of local material for sustainable, ecological and environmentally friendly construction. 100% recyclable materials with a low economic and energy cost, which enables constructing healthy and efficient habitats.

As accredited consultants in eco-innovation, we work in various areas of research, searching for new products and building systems with rammed earth. We study the properties of the materials and the optimal composition for obtaining maximum benefits, while we open the way for their standardisation and adaptation to current legislation as members of the Technical Committee UNE-CTN 41/SC 10.

Please, introduce yourself and your Studio…

Maite Sainz de la Maza, architect and Macari de Torres, geologist engineer, founders of Fetdeterra, Innovative Earth Projects and Products.

We are technical specialists in rammed earth architecture and accredited consultants in eco-innovation, product design and technological development.

We work with users, technicians and manufacturers from the very first stages of the project to find the solution that best suits their needs.

We want to promote the use of local material for sustainable, ecological and environmentally friendly construction. 100% recyclable materials with a low economic and energy cost, which enables constructing healthy and efficient habitats.

As accredited consultants in eco-innovation, we work in various areas of research, searching for new products and building systems with rammed earth. We study the properties of the materials and the optimal composition for obtaining maximum benefits, while we open the way for their standardisation and adaptation to current legislation as members of the Technical Committee UNE-CTN 41/SC 10.

How did you find your way into the field of Architecture and Geological Engineering?

We loved the rammed earth architecture, we wanted to live in a natural way, we believed in a sustainable architecture, and the earth was a material, that could give us this kind of construction without waste, no toxic, and we can used to make our homes more healthy.

What comes to your mind, when you think about your diploma project?

Our diploma project was very different that the projects we do now.

Nowadays we have more experience about our work, and we know that in our diploma project are mistakes, and if we do it another time, we change many things.

What are your experiences founding Fetdeterra? When did you decide to partner up? Which project started your practice?

In 2017 we created the company Fetdeterra SL, due to the growth of our own business. Years before we specialized in rammed earth construction for several reasons, we combine our knowledge, Macari had a lot of experience in the work, and as a geological engineer, he knew the material very well, and Maite provided the most functional and aesthetic part, as an architect. Also the environmental benefits and properties of the earth such as the regulation of humidity and temperature, breathability, thermal inertia … fit with our vision of sustainable architecture for the future.

Our customers are technicians and companies linked to architecture and construction, with interest and sensitivity towards innovation and sustainability.

The earth box was the first project we built with natural materials, only wood and earth, we get not generate waste in construction, we designed the wooden formwork, for the earth walls, to reuse it on the roof, pavement, carpentry and furniture.

How is the context of Lleida, where your office is based, influencing your work?

Where we live there are a lot of old rammed earth constructions, some of these constructions made 100 years ago, and there are still, this influenced us to specialize in rammed earth architecture. We perceive a growing increase in the demand for a more natural and sustainable architecture, at the same time that, the need to rehabilitate our existing earth heritage, in parallel with these needs, there are the problems of ignorance of the earth as construction material, and the uncompetitive execution of the traditional construction system, these problems generate a series of basic doubts such as the dosage of the earth, the quality control, the technical prescriptions, the justification of the Technical Code, among others …

Then we saw the need to specialize, in order to help technicians and builders to develop their projects. Later on as accredited advisors in Eco-innovation, we created the I+D+I department, from which we have obtained products such as the prefabricated raw earth block Tapialblock, with which we solve the problem of ignorance of the material, the justification of regulations and the expensive execution of the traditional system of earth construction.

Tapialblock is an eco-innovative product from its formulation until its manufacture and reuse. Composed of 100% recyclable natural materials and manufactured with the minimum energy cost. Thinking about health and benefit for the user, and sustainability for the environment.

What does your desk/working space look like?

We have different workspaces, We have two lines of work within the company, projects and products. We develop architecture projects, advice, I+D+I projects, and we manage the standardization and commercialization of raw earth products.

We work in a coordinated manner, and jointly decide the actions and general objectives of the company, although each one carries out different tasks, Macari supervises the subject of laboratory, materials and work execution, and Maite writes the projects and designs. We have formed an external team of expert collaborators each in a specific topic. We filter all the work and decide how the different projects will be developed according to our needs. New technologies are fundamental, It also facilitates our work, with the systematization of processes and the possibility of creating this external team of collaborators, with which we can work together remotely.

What is the essence of architecture for you personally?

The essences is the research and innovate into the sustainable architecture. We believe that we cannot innovate, if we don’t know and understand the material and the construction system, that is why we have studied, and continue to study it from the base, through standardized laboratory tests, in order to obtain the objective data that we will use, to compare and improve the project and / or product. We must give a technical response to current needs, adapting the natural material for construction, and take advantage, at the same time, technologies developed in recent years in the world of construction and industrialization.

Rammed Eath Blocks

Rammed Earth Blocks

Your master of architecture?

We have different references that are not exclusive to the world of architecture, but perhaps we would highlight the work started by Miguel Fisac, with concrete research and product development, that study and endless search within the limits of the material itself. More people who works and investigates with the material, Solano Benitez with ceramic block, and of course, Martin Rauch with rammed earth.

From your point of you, what is sustainable / environmentally friendly Architecture?

The material we use for build is very important for us, we appreciate a change in the architecture and in the vision of the architects themselves, we see a tendency to simplify the use of materials for construction, as well as the increase in the valuation of those simpler and more natural materials, without coatings, and we think that is a good way for doing a sustainable and environmentally friendly architecture.

What has to change in the Architecture Industry?

How do you imagine the future? In the world of architecture, it would be necessary to take into account the useful life of the materials that have been used and are being used today, not only the energy cost of their manufacture, but also thinking about their end, and the consequences for the environment, How will this diversity of industrialized materials be recycled? How to avoid a negative impact on the environment?

Project

FETDETERRA

STAND AT CONSTRUMAT

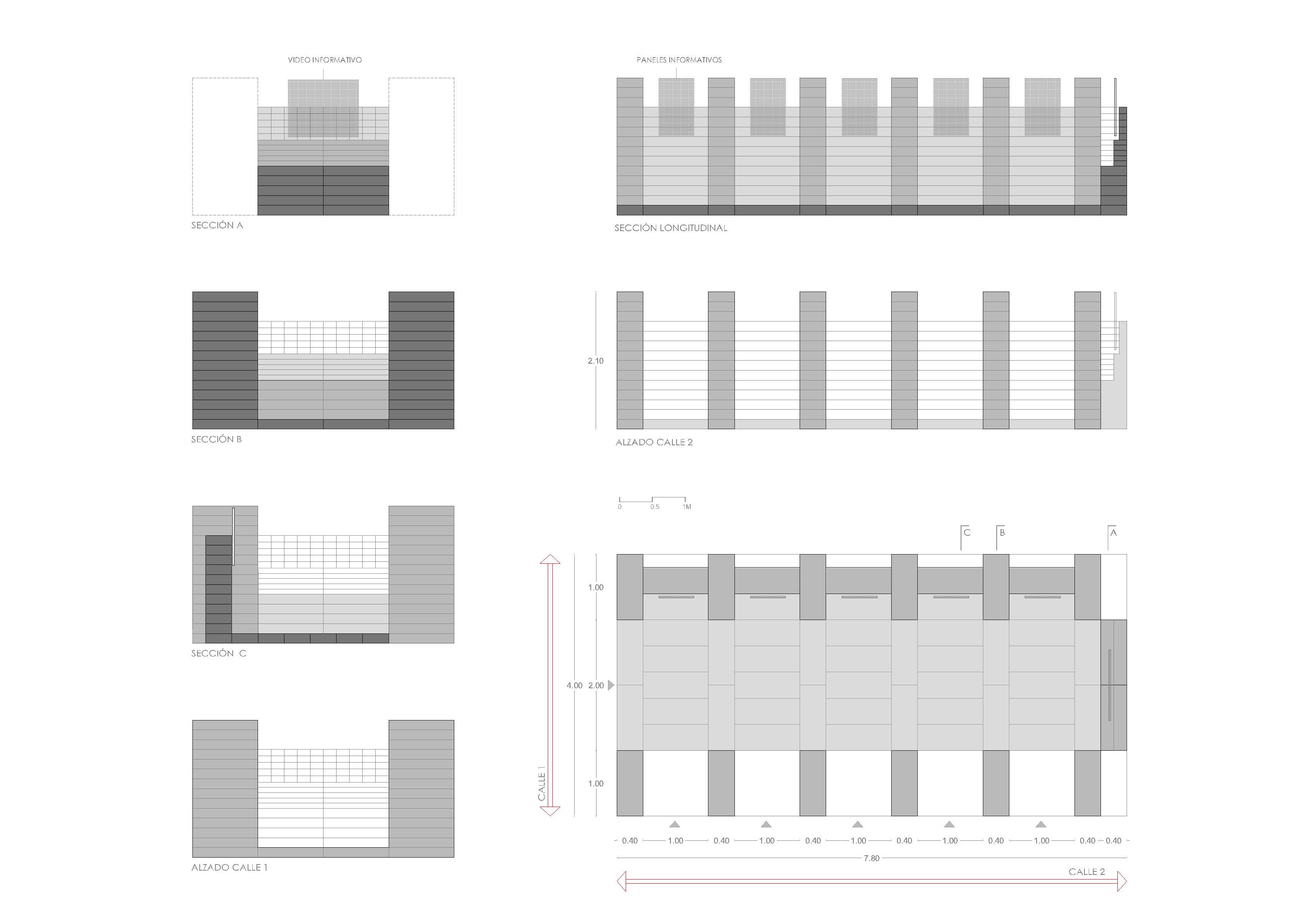

The objective of the Fetdeterra stand at Construmat, was the presentation of Tapialblock, a prefabricated raw earth block. The stand was designed with the premise of coherence among the stand and the new product. Our efforts were focused on enhancing the presence of the material, and turning the visit to the stand into an experience to enjoy the sensations transmitted by the material itself.

Design Bases of:

• Use of a single material, the earth.

• Quick assembly and dismantling, thanks to the prefabricated system.

• The blocks are dry placed, to be able to reuse 100% of the blocks, and not generate any waste.

• Minimize costs in material, assembly and disassembly.

With this project, we obtain a positive social impact of the acceptance of the product, which is confirmed with the 1st prize obtained as innovative material at the fair. Minimal impact on the environment, achieved through the non-generation of waste, before, during or at the end of the event. Low economic impact by eliminating the cost of the material, by reusing 100% of the product, the blocks are recovered and then placed in another project