21/002

t-lab

Research Lab

Kaiserslautern

«I am convinced that cycle-efficient construction is revolutionising the building industry climate-wise, as the resource-efficient reuse of building products, building units, and building components is redefining construction in its tectonics, panelisation and joining.»

«I am convinced that cycle-efficient construction is revolutionising the building industry climate-wise, as the resource-efficient reuse of building products, building units, and building components is redefining construction in its tectonics, panelisation and joining.»

«I am convinced that cycle-efficient construction is revolutionising the building industry climate-wise, as the resource-efficient reuse of building products, building units, and building components is redefining construction in its tectonics, panelisation and joining.»

«I am convinced that cycle-efficient construction is revolutionising the building industry climate-wise, as the resource-efficient reuse of building products, building units, and building components is redefining construction in its tectonics, panelisation and joining.»

«I am convinced that cycle-efficient construction is revolutionising the building industry climate-wise, as the resource-efficient reuse of building products, building units, and building components is redefining construction in its tectonics, panelisation and joining.»

Please, introduce yourself and the research group “t-lab — Holzarchitektur und Holzwerkstoffe” at the Fachbereich Architektur Technische Universität Kaiserslautern (fatuk)…

Stephan Birk: Jürgen Graf was appointed as a civil engineer to the professorship “Tragwerk und Material” (Structures and Materials) in 2013, and I was appointed as an architect to the professorship “Baukonstruktion und Entwerfen” (Building Construction and Design) at fatuk in 2015. At that time, the department already had the idea to set up a research lab for wood construction and staffed the two key professorships accordingly.

The “t-lab Holzarchitektur und Holzwerkstoffe” has existed in this form since 2015 with a steadily increasing number of projects. We feel equally committed to teaching, i.e. training students in this subject area, and to conducting research. Our overarching goal is to increase the proportion of wood used in construction to substitute as many mineral building materials as possible.

Jürgen Graf: Before t-lab, Technical University of Kaiserslautern did not have a wood construction research lab. At the Department of Architecture, we had the great opportunity to establish an integrated wood construction research lab focusing on design and construction—as practiced only at the Technical University of Munich in Germany. Very soon, we realized that we would have to set up an interdisciplinary research program. Consequently, our research projects increasingly encompass complex issues relating to timber structures from a design, construction, fire protection, building physics, supply and ecological point of view. Several collaborative research projects from different disciplines have been initiated and successfully carried out meanwhile.

How is the relation between theory and practice at t-lab and why is the topic you are working on important for architects?

JG: CO₂ emissions, resource and energy consumption, water consumption and waste generation are so high with current construction methods that the resulting environmental impacts are a significant contributor to anthropogenic climate change. The construction industry (building, operating, and demolishing) is the largest CO₂ emitter worldwide and consumes most of the resources (Graf, 2020). Furthermore, in view of the fact that the world’s population is increasing by around another 30% climate-efficient construction is paramount.

A revolution in efficiency through disruptive technologies is therefore clearly needed to reduce the consumption of resources and energy in the building sector. This requires research in the areas of standardised and modular construction methods for homes and workplaces, reversible connections, material research on wood and hybrid material combinations, material cycle efficient planning processes and economical production methods, re-densification and refurbishment of existing buildings, sufficiency strategies to avoid waste, recycling and reuse of deconstruction materials, as well as the classification and cataloguing of research results to make them available to building contractors and all other stakeholders involved in the building, operating, and demolishing process of a building.We address these challenges in theory and practice in the research programme “t-lab– Holzarchitektur und Holzwerkstoffe”.

SB: We focus on applied research and rely on an applied teaching method. Of course, theory is the basis of our work, but at t-lab we focus primarily on implementing the insights we have gained.

What does your desk/working space look like at the moment?

SB: Due to the pandemic, almost everybody works from home, and we discuss ongoing projects via video conferences. It’s not always easy, but it works quite well. In February (after some delay), the construction of our t-lab workshop and research hall in Diemersteiner Tal is finally due to start. Then for a few weeks our workplace will be outdoors, on the construction site

How do you define the following words and what do they mean to you?

Resilience…

SB: A buzzword, I think! At present, I cannot see any broad-based ability on the part of humankind to cope with the climate crisis. Although, the fact that the term exists in psychology gives me hope...

Sustainability…

SB: Environmental compatibility. Balance, harmony. Important at all levels, should be the basis of our actions. Applies not only to architecture, but to everything.

Circularity…

JG: I am convinced that cycle-efficient construction is revolutionising the building industry climate-wise, as the resource-efficient reuse of building products, building units, and building components is redefining construction in its tectonics, panelisation and joining.

CO₂-Pricing…

JG: Is a central instrument in climate policy, given that it is used worldwide and imposes a high price on the consumption of fossil energy. An incentive ought to be given for the supply of solar and wind energy (wind turbines and upwind power plants) as well as for hydrogen as an energy source. Emerging economies and developing countries would thus be enabled to produce “clean” energy to generate prosperity.

Cradle-to-Cradle…

JG: Varietal purity, biological and technical cycle—as a principle the prerequisite for an effective circular economy.

What is your favourite building material and why?

JG: From my point of view, this question can no longer be posed independently from the climate crisis. It can only be answered in conjunction with the climate-relevant question on how humanity’s desire (craving) for prosperity can be reconciled with drastic resource conservation. It means disentangling growth from resource consumption. This is why we must strive for efficient, consistent and sufficiency-oriented construction. From a design point of view, it is logical that wood is the ideal material.

SB: Wood is a renewable resource. It absorbs CO₂ and has great material properties if you apply it in the right way. To me, the great attraction lies mainly in the aesthetic potential of the material. If we use wood to design and build in a way that is appropriate to the material, I am convinced that we can achieve a different architectural expression.

How do you translate the knowledge that you are gathering through t-lab as a research project into teaching?

SB: Together as t-lab, Jürgen Graf and I run courses, including design projects, lectures and workshops. This has already enabled us to incorporate research content into teaching on several occasions. Last summer, for example, a team designed high-rise buildings made of hardwood in which dwarf rice is grown for the residents’ self-sufficiency. The background to this is a broader research project that we would like to embark on in the near future in cooperation with other universities. The results were remarkable, the mix of occupation for rice cultivation and housing led to a whole new typology! In another course, students designed outdoor furniture made of acetylated pine before they built them 1:1.

JG: We also aim at teaching our students how architecture and construction interrelate in design-build projects. The students dealt with all facets of architectural and constructional issues from the initial design idea to the completed building. One example is the design-build project “Gemeinschaftshaus Flüchtlingsunterkunft Spinelli, Mannheim”, which was realized in 2016 together with Stefan Krötsch, Andreas Kretzer, architecture students from TU Kaiserslautern, refugees and the city of Mannheim. It has won numerous national and international awards.

Are there other projects that you perceived as good example for energy efficient building? How did theseprojects influence your work?

SB: Of course, we are in exchange with other research institutions, be it through collaborative work on joint projects, within the scope of conferences (e.g. FORUM HOLZBAU or Deutsche Holzschutztagung) or by studying publications. During a conference, for instance, we learned about the start-up Restado/Concular, and we were very enthusiastic about the concept.

What essential actions do we need to take as architects now regarding a more sustainable future for everyone?

SB: We all know what needs to be done! A key approach is to drastically reduce CO₂-emissions throughout the construction process. This means that mineral building materials are to be substituted by renewable ones. It is important to take a holistic view, from the production of building materials, through the construction phase and operation, to deconstruction and recycling, right from the start.

JG: Consequently, we address structures for unspecified occupancy and life-cycle-efficient construction methods as well as waste avoidance strategies through refurbishment instead of demolition, and the question of whether a construction measure is necessary.

From your perspective: What are the political and legislative influencing factors that matter most?

SB: As always, incentives are needed to implement the findings on a broad scale. The construction industry is currently purely price-and profit-driven. With few exceptions, it’s all about building as cheaply as possible. This must change! Planning and building economically must necessarily mean that new buildings are climate-neutral.

Grants and subsidies for building with renewable raw materials are just as necessary as the questioning of standards. I am convinced that there will be no change in the building industry without stipulations or even compensation payments for particularly CO₂-intensive construction methods.

JG: A necessarily rapid, climate-relevant change in the construction industry—the efficiency revolution—requires disruptive technologies in design, prefabrication and construction of buildings, which can only be achieved through the political will to back massive research funding. Effective, circular measures must be politically stipulated and promoted.

What needs to change in the field of architecture according to you? How do you imagine the future? Imagine it is 2050: What is your personal utopia? Tell us about the most positive vision you have?

JG: In my view, circular construction must be the standard throughout the country by 2050. The disentangling of growth and resource consumption must prevail beyond the building sector.

SB: A cultural change is needed, at all levels. As architects and engineers, we are particularly in demand because we have excellent problem-solving skills. This is what we will need to focus on to meet the challenges of architecture in the age of the climate crisis. Change inevitably involves reconciling building culture and climate justice. That is my vision for 2050!

Imagine you have the power to change the world: If there were one thing you could change right here right now, what would it be?

JG: Consistent worldwide research and economic action to drastically save resources and energy whilst increasing prosperity. By the way: in a similar way as research into and “marketing” of vaccines (and possibly medication) to cope with the Corona crisis currently seems to be succeeding!

SB: At last, we are taking the necessary action at all levels worldwide in response to the climate crisis.

If there were one skill you could recommend to a young architecture student to focus on in depth at architecture school: what would it be and why?

JG: Green design and construction, because we must prevent future climate catastrophes.

SB: Designing and engineering in cycles, that is the pressing matter of our time, in order to change the future.

What person/collective/institution or project do we need to look into right now?

Restado/Concular, as mentioned above.

What book/paper/info-resource of any kind do we need to look into, to educate ourselves on the topic of resilience/sustainability/materiality/etc.?

Braungart, M.; McDonough, W. (2002) Cradle to Cradle: Remarking the Way We Make Things, New York: North Point Press

Graf, J. (2020) Entflechtung von Wachstum und Ressourcenverbrauch – Zirkuläre Wertschöpfung im Holzbau. In: Bautechnik 97, Sonderheft Holzbau, Ausgabe 2, S. 108-115.

Hillebrandt, A. et al. (2018) Atlas Recycling – Gebäude als Materialressource.1. Aufl. München: Detail Business Information GmbH.

Kaufmann, H.; Krötsch, S.; Winter, S. (2017) Atlas Mehrgeschossiger Holzbau. 1. Aufl. München: Detail Business Information GmbH.

Meadows, D. et al. (1972) The Limits to Growth: A Report for the Club of Rome's Project on the Predicament of Mankind.

Weizsäcker, E. U. et al. (2009) Factor Five. Transforming the Global Economy through 80% Improvements in Resource Productivity. Earthscan, London.

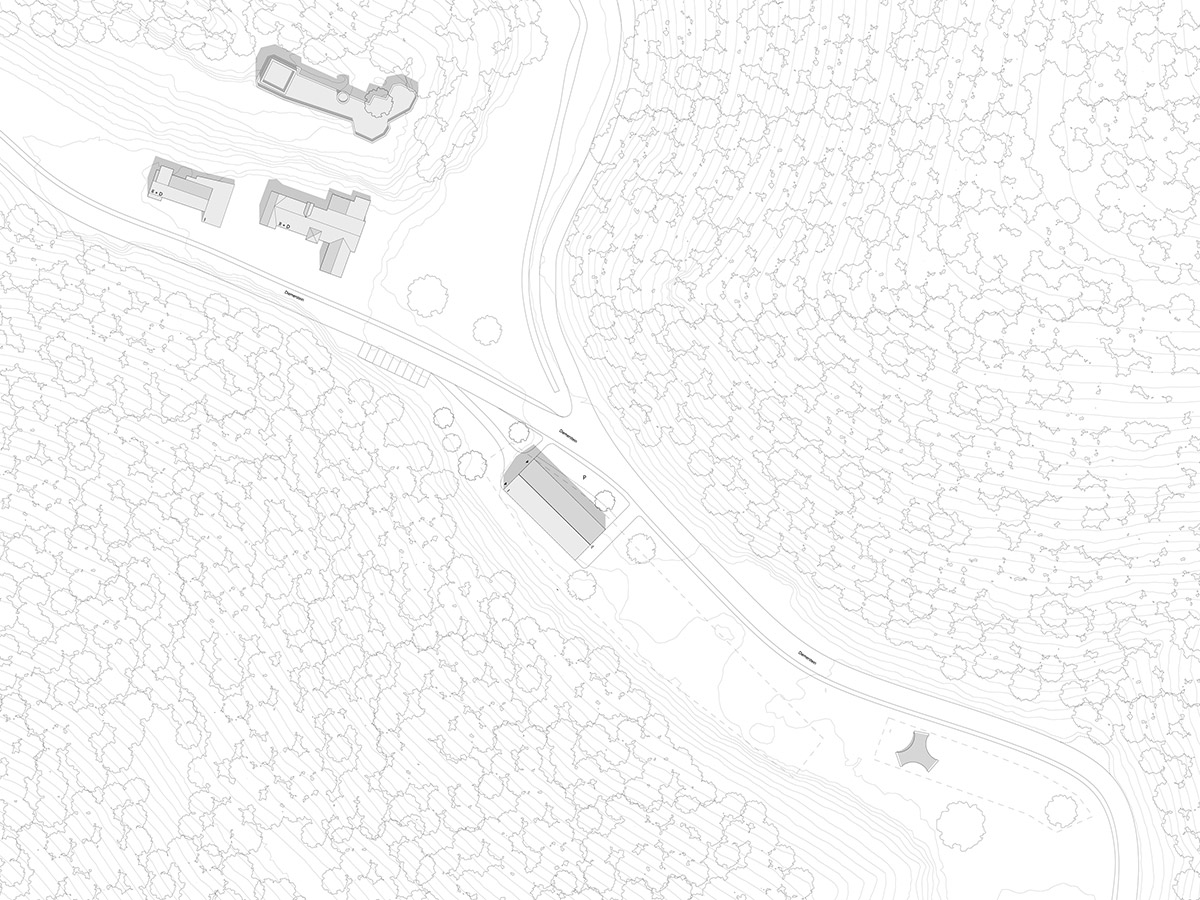

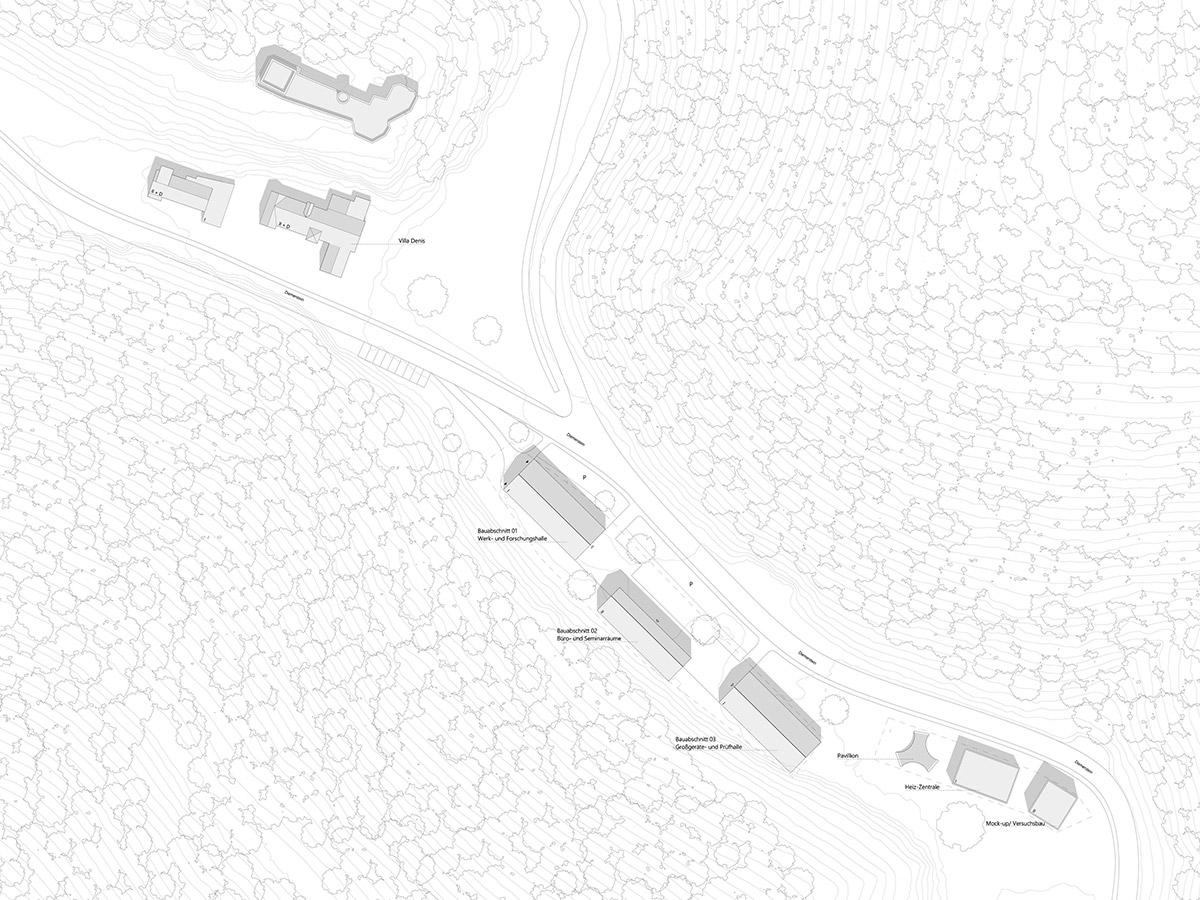

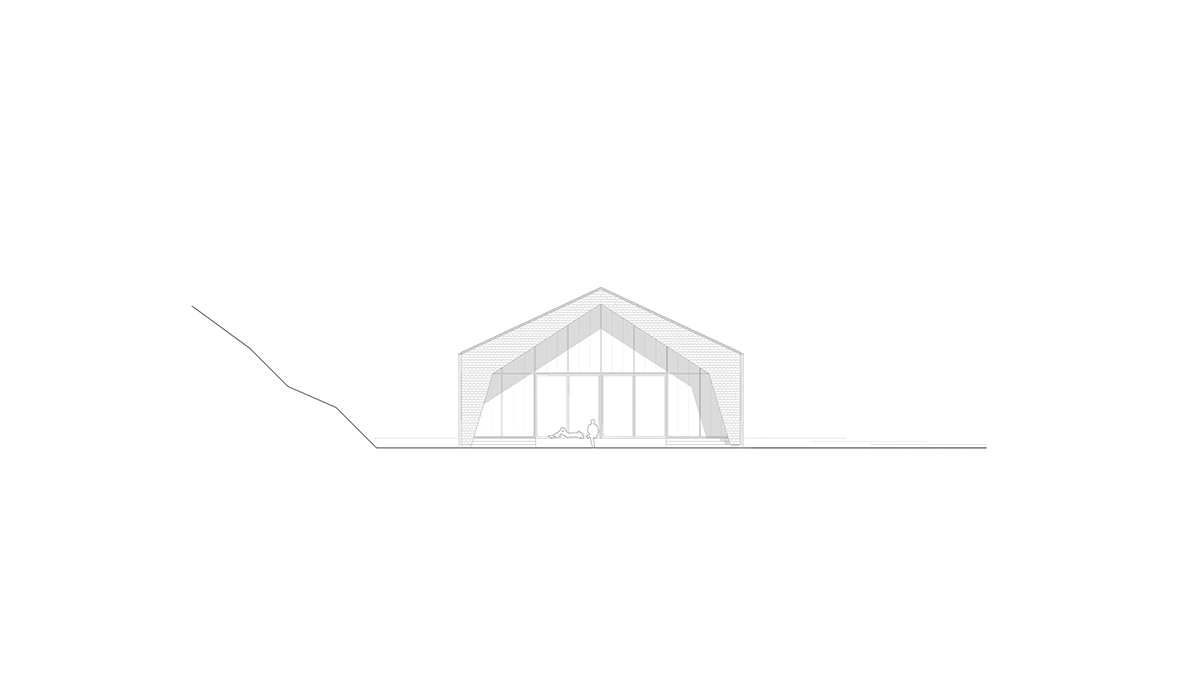

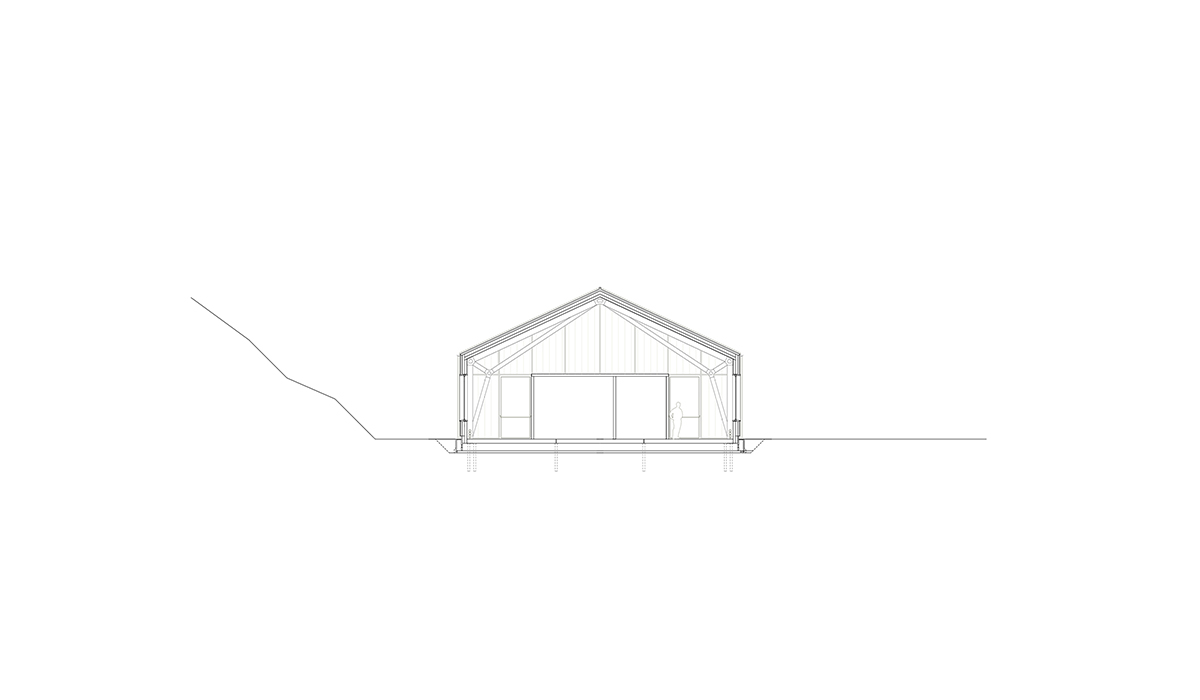

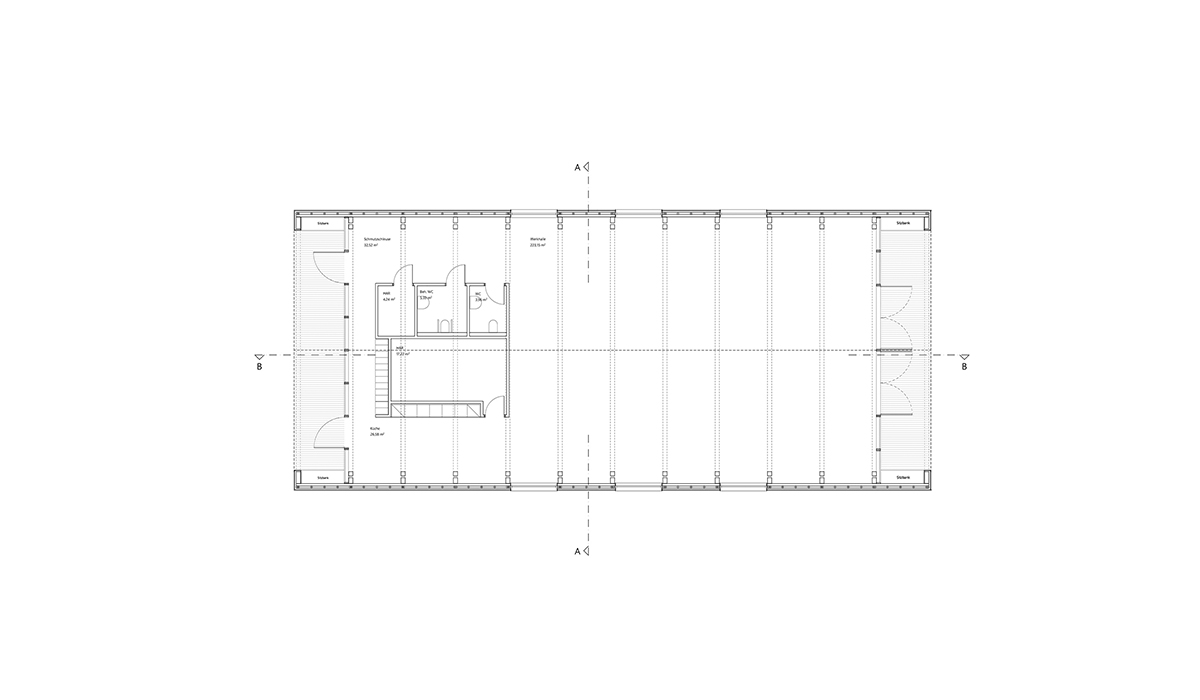

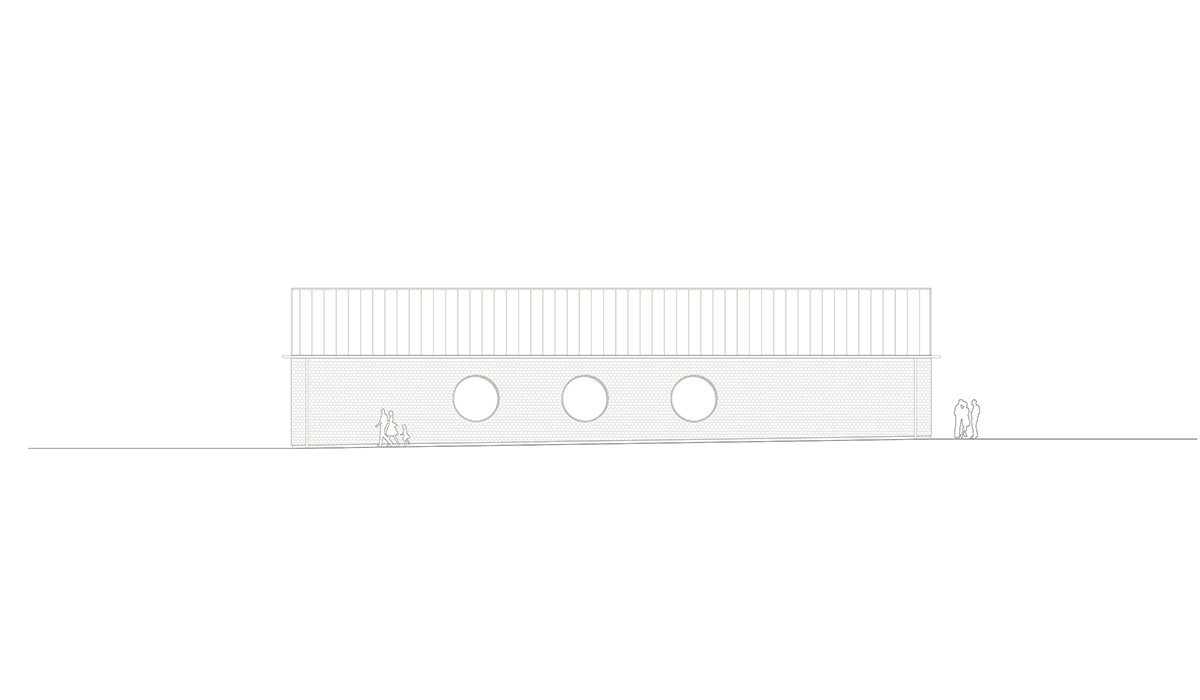

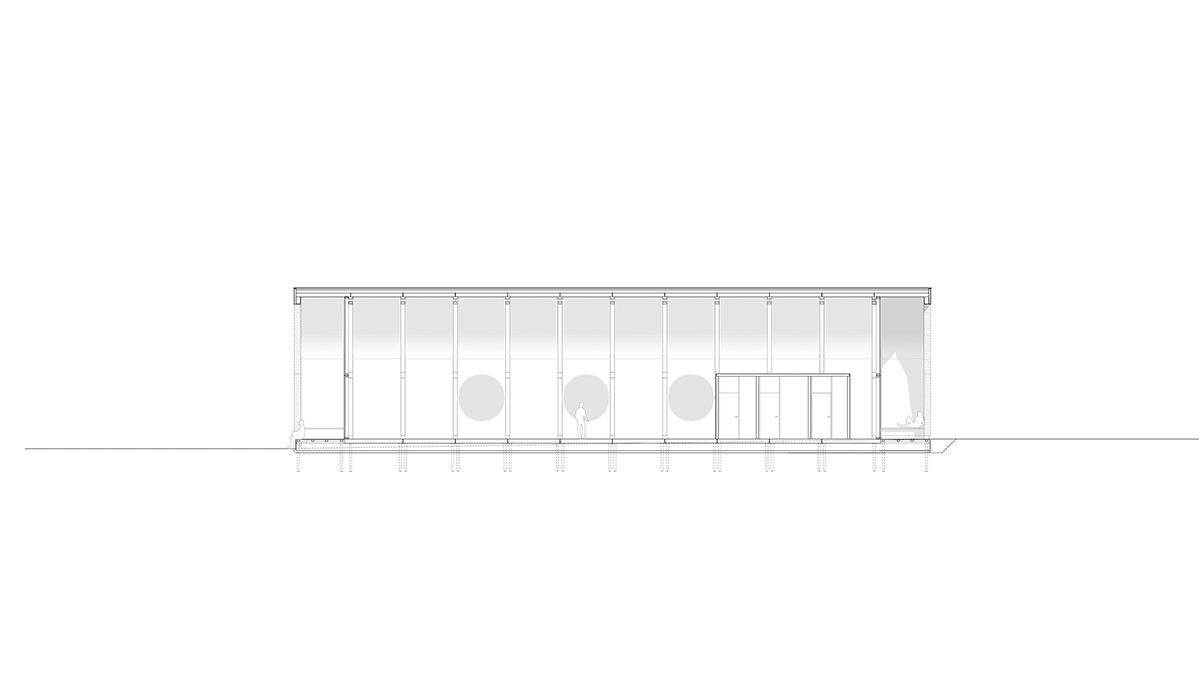

Project 1

Workshop and Research Hall

Diemerstein

In the middle of the Palatinate Forest, we are planning a campus for innovative and experimental wood construction with t-lab and many cooperation partners. Construction is now about to begin on the initial building, a workshop and research hall. The building, which measures around 360 square metres, offers a versatile interior space that can be used for workshops, seminars and events, as well as for the construction and assembly of mock-ups and prototypes as part of ongoing research projects. The new structure is situated longitudinally in the valley. Wood will be used for the primary construction, the façade and the finishing. Components are designed to be dismantlable and reusable. Structural members, the envelope and the technical installations remain identifiable. The new building derives its architectural form from the genesis of the demand for consistent recycling management of all building products, building units, and components.

Renderings: Nikolai Becker Images, Stuttgart

Drawings: t-lab

Model photography: Bernhard Friese, Pforzheim

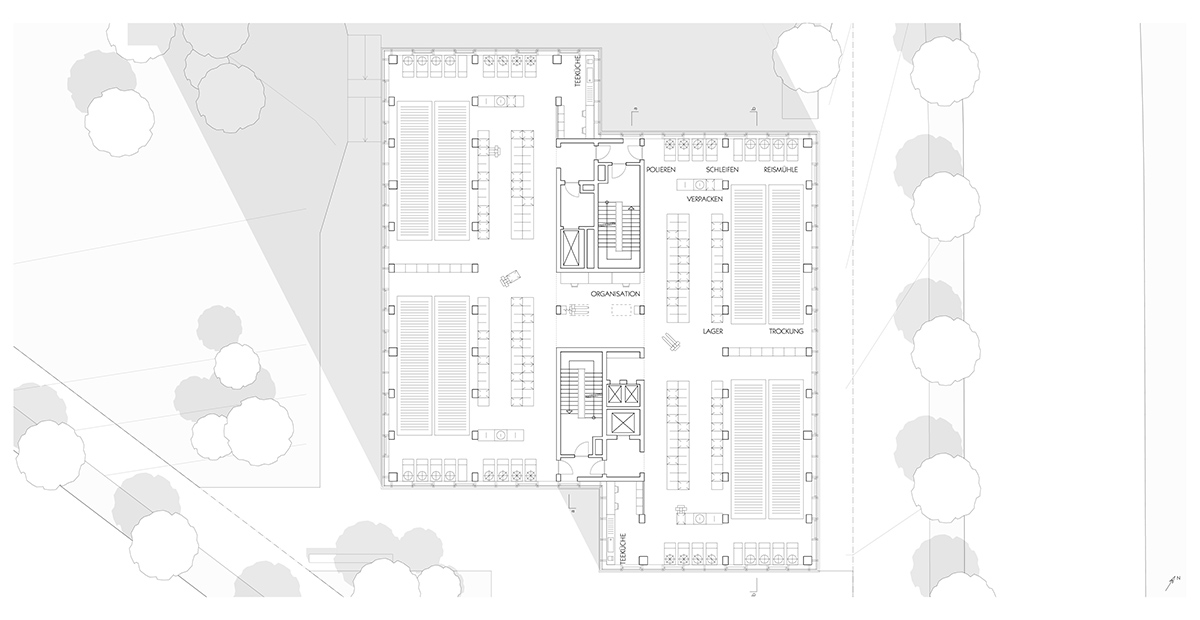

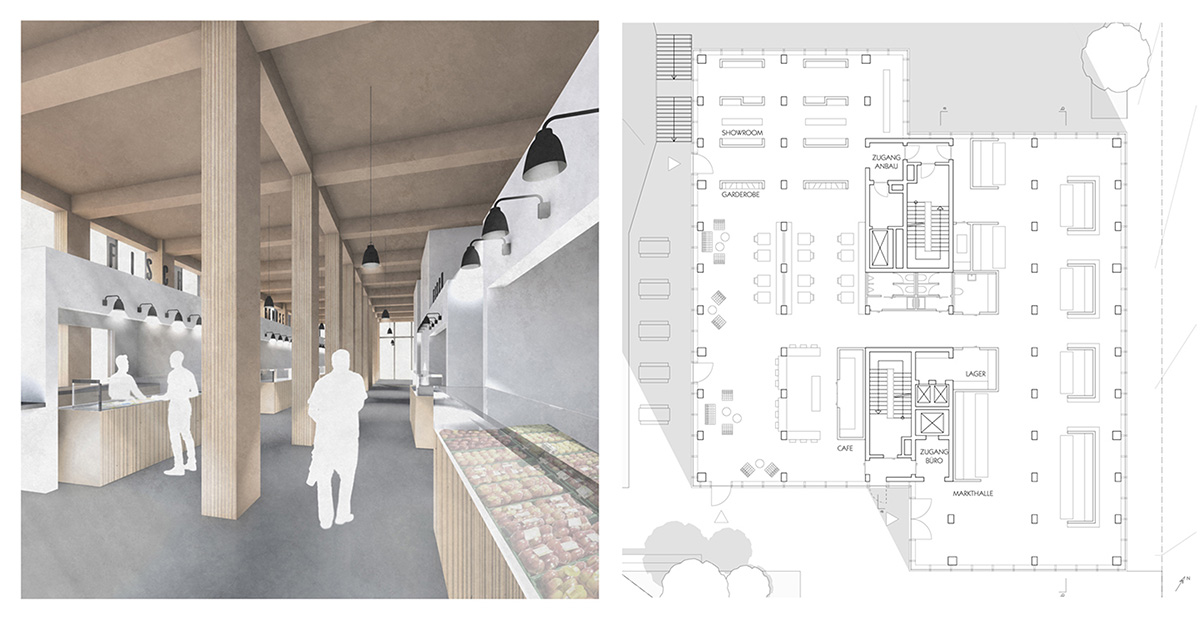

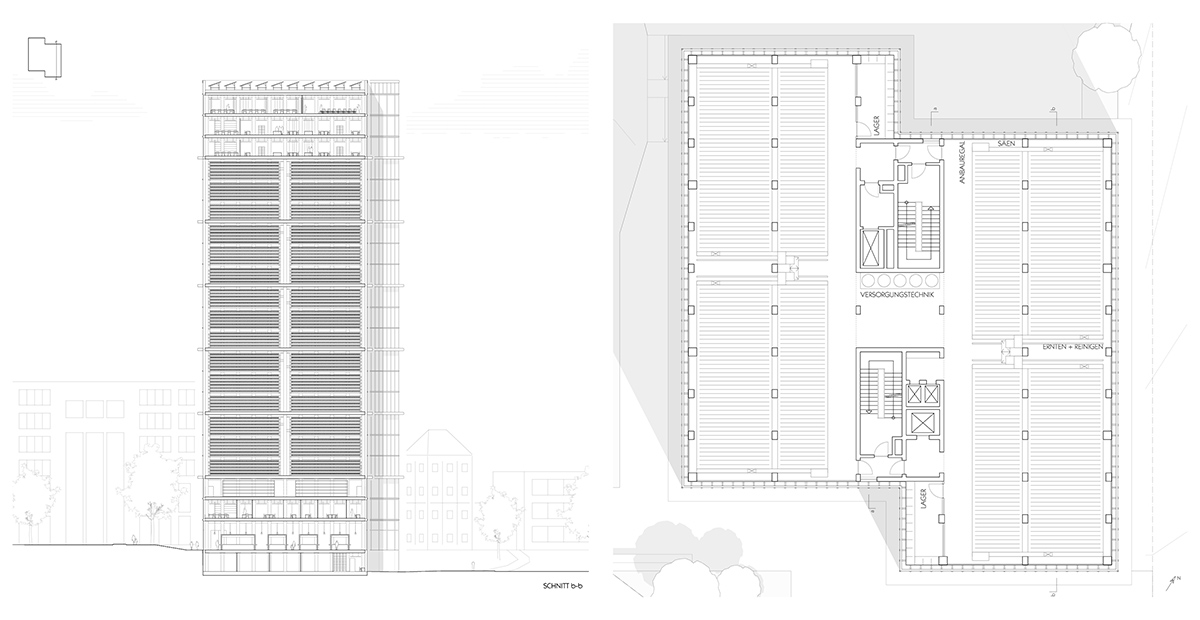

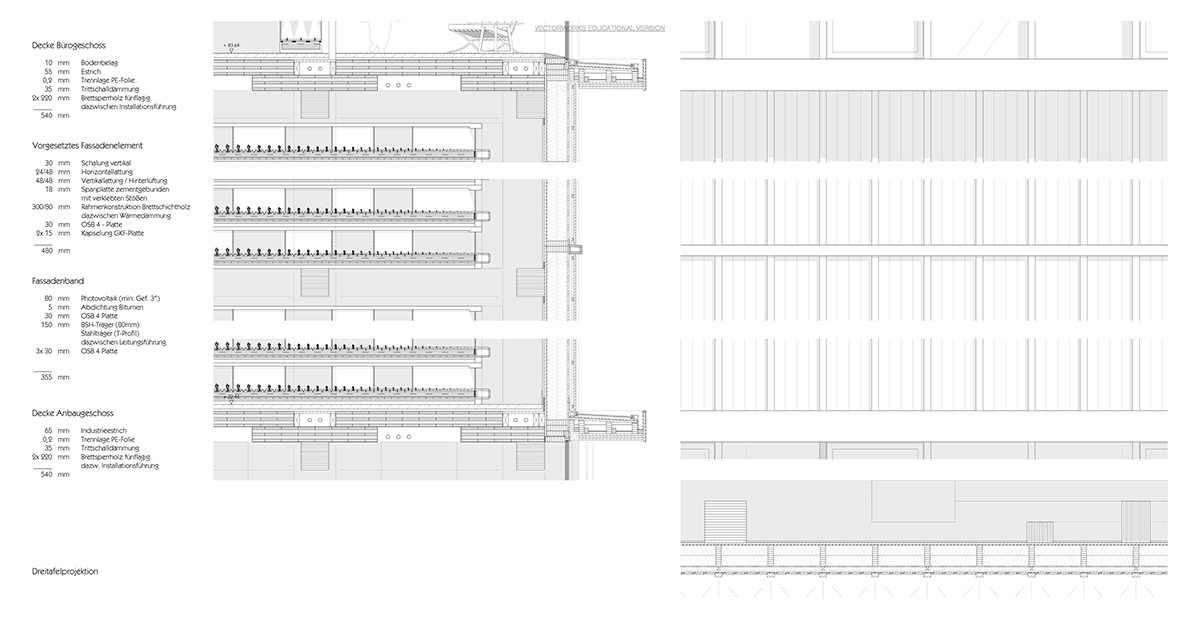

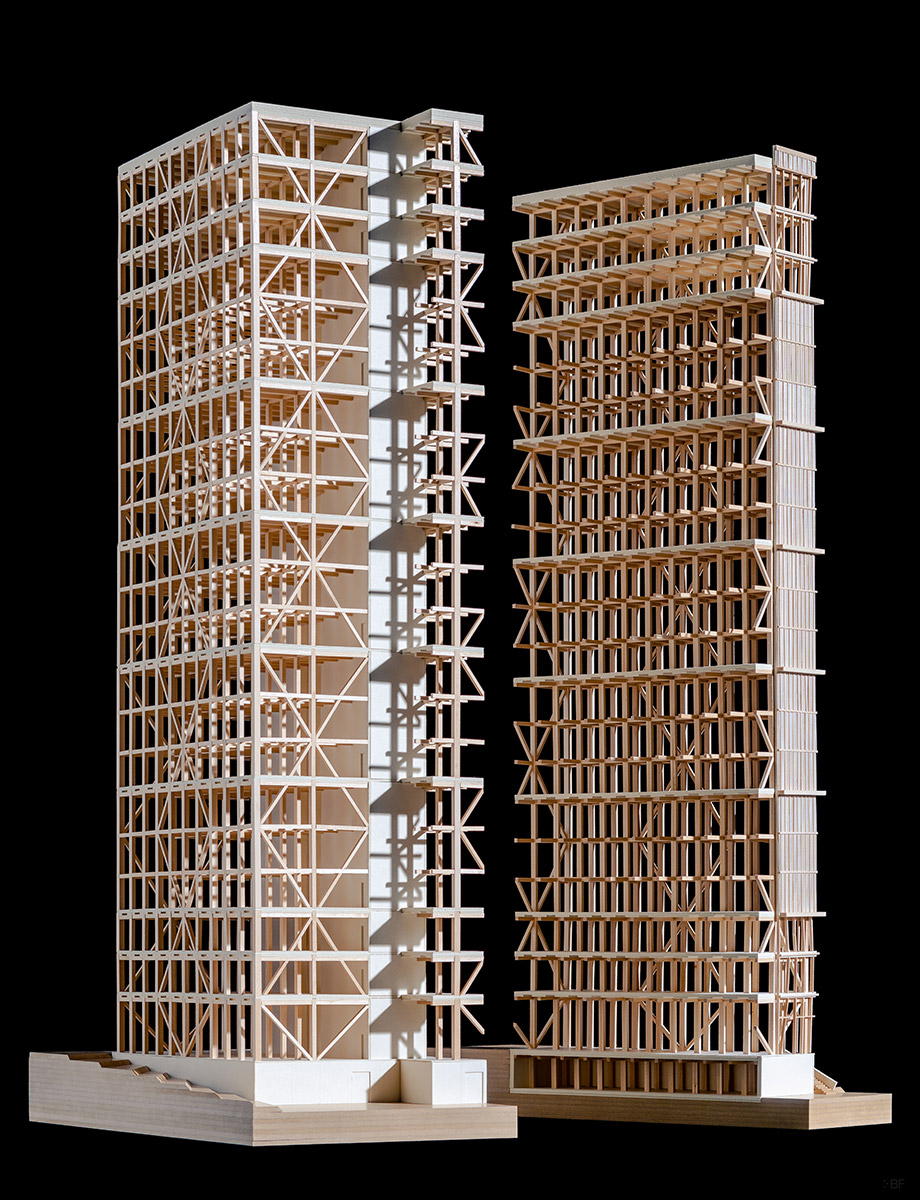

Project 2

Timber High Rice

Student project by Johannes Kasseland Katharina Sondenheimer

The overall objective of the project is to work in an interdisciplinary research team with playersfrom science and industry to make a significant contribution to climate protection, circular value creation, the basic supply of the world population with staple food, and to more urban housing construction. As part of the design project for the Master’s programme at fatuk, the students were asked to develop a building that could be used for a mix of housing and rice cultivation in controlled environment farms (CEF).The project by Katharina Sondenheimer and Johannes Kassel proposes a market place with café and showroom on the ground floor. The dwarf rice is processed and refined on the floors above. Beginning from the fourth floor upwards is the rice cultivation and space for potential apartments. The load-bearing structure of the building comprises columns and wind bracing made of hardwood (beech), cross-laminated timber ceiling elements and a central core of reinforced concrete.

Drawings: Katharina Sondenheimer & Johannes Kassel, fatuk

Model photography: Bernhard Friese, Pforzheim

t-lab: www.architektur.uni-kl.de/tlab, @tlab_de

fatuk: www.architektur.uni-kl.de/, @fatuk_de

bhundf: www.bhundf.com, @bhundf

Interview: kntxtr, ah+kb, 01/2021